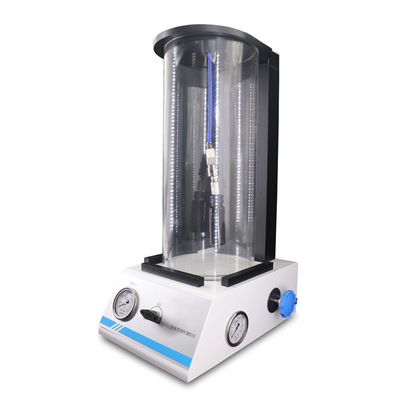

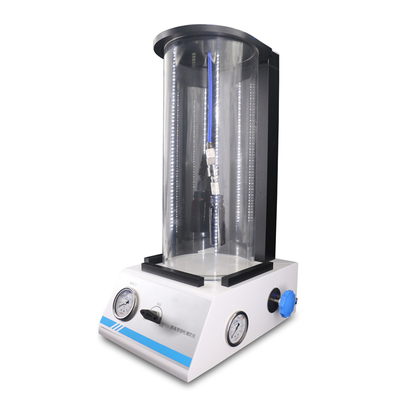

ISO 13845 ASTM D2063 ASTM F2095 병 캡 밀폐 검사기

병 캡 밀폐 테스트는 가스 누출을 방지하기 위해 병과 통조림 음료 뚜?? 의 밀폐 성능을 측정하여 포장 밀폐의 품질을 효과적으로 제어하는 데 사용됩니다.

그것은 PET 병, 유리 병, 캔 제품을 테스트하는 데 적합하며, 또한 왕관 캡과 PET 병 캡의 밀폐 성능을 독립적으로 측정합니다.

병 뚜?? 종류:

탄산 PET 병 음료

크로나 캡이 있는 알루미늄 병

탄산화탄소가 없는 PET 병 음료

통조림 음료

크로나 뚜?? 이 있는 유리 병

알루미늄 나사 뚜?? 이 있는 유리 병

병/통 폐쇄에 대한 정당한 밀폐 표준:

탄산 PET 병 음료 (예: 콜라): 1.0 MPa

탄소가 없는 PET 병 음료 (예를 들어, 미네랄 물, 차): 0.2 MPa

크라운 캡/알루미늄 스크루 캡 (예: 맥주): 1.0 MPa

플라스틱/알루미늄 나사 뚜?? 이 있는 탄화탄소가 없는 유리 병 (예를 들어, 소야 소스, 바이지우): 0.2 MPa

탄산 음료 (예: 맥주, 콜라): 1.0 MPa

탄산화탄소가 없는 음료 캔 (예: 허브 차): 0.2 MPa

검사기는 물에 잠겨있는 샘플을 압력화하여 밀폐에서 거품 형성을 관찰하여 누출을 감지합니다.

특징 및 사양:

압력 소스: 압축 공기 또는 CO2

양압 방법: 진공 기반 시험의 한계를 극복합니다 (<1 바).

압력 범위: 0~16bar (1.6MPa)

건축물: 안오디스 된 알루미늄, 스테인리스 스틸, 그리고 플라스틱으로 장수합니다.

내장 압력 조절기: 최대 시험 압력을 쉽게 설정합니다.

안전 특징:압 완화 밸브, 안전 밸브 및 버킷 뚜?? 안전 잠금 장치

(물 버킷이 봉쇄되지 않은 경우 테스트 중지) 배기가스 포트를 통해 가스의 빠른 환기 (시작하기 위해 뚜?? 을 닫아야 합니다; 들어올리는 뚜?? 은 즉시 압력화됩니다.)

정밀한 흐름 제어: 조절 가능한 압력화 속도 (1 MPa에 도달하기 위해 5~60초)

높은 민감성 및 정확성:

| 압력 측정기 해상도 |

00.05MPa |

| 지각 범위 |

0.1.6 MPa |

| 최대 표본 크기 |

330 × 150 mm (H × D) |

| 크기 |

320 × 380 × 720mm (L × W × H) |

| 순중량 |

15kg |

시험 원칙:

닫기 밀폐 검사기는 PET 음료 병 뚜?? 의 밀폐 성능을 검사하는 데 사용됩니다. 테스트 중에 표본은 물 탱크에 배치됩니다.그리고 특정 양의 가스가 표본의 상부에 주입되어 정상적인 대기 조건 이상의 내부 압력을 증가시킵니다., 이를 통해 샘플의 폐쇄의 밀폐 무결성을 테스트합니다.

정당한 밀폐 성능을 가진 샘플은 누출의 징후를 나타내지 않고 추가 압력을 견딜 수 있습니다.컵 영역에서 거품이 나타날 것입니다, 이는 조작자가 쉽게 관찰 할 수 있습니다. 액체 누출보다는 가스 누출을 감지함으로써 측정 민감도가 최대화됩니다.

시험 표본 안의 압력은 압력 절감기를 통해 제어 할 수 있으며 압력 가스의 흐름 속도는 흐름 제어 밸브를 통해 조절 할 수 있습니다. 가스 압력을 조절함으로써,운영자는 누출이 발생하기 전에 밀봉이나 용기에 견딜 수 있는 최대 압력을 결정할 수 있습니다.가스 흐름 속도를 조절함으로써 더 정확한 내부 압력을 설정할 수 있습니다.가공자가 누출이 발생하는 압력 값을 읽고 밀폐 장애의 심각성을 평가할 수 있도록.

ZL-9025C 폐쇄 밀폐 검사기는 안전 밸브, 기기 덮개에 있는 빠른 가스 배기가스 포트, 안전 뚜?? 잠금, 압력 절감기,그리고 시험 샘플을 침몰시키기 위한 유통형 물탱크.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!